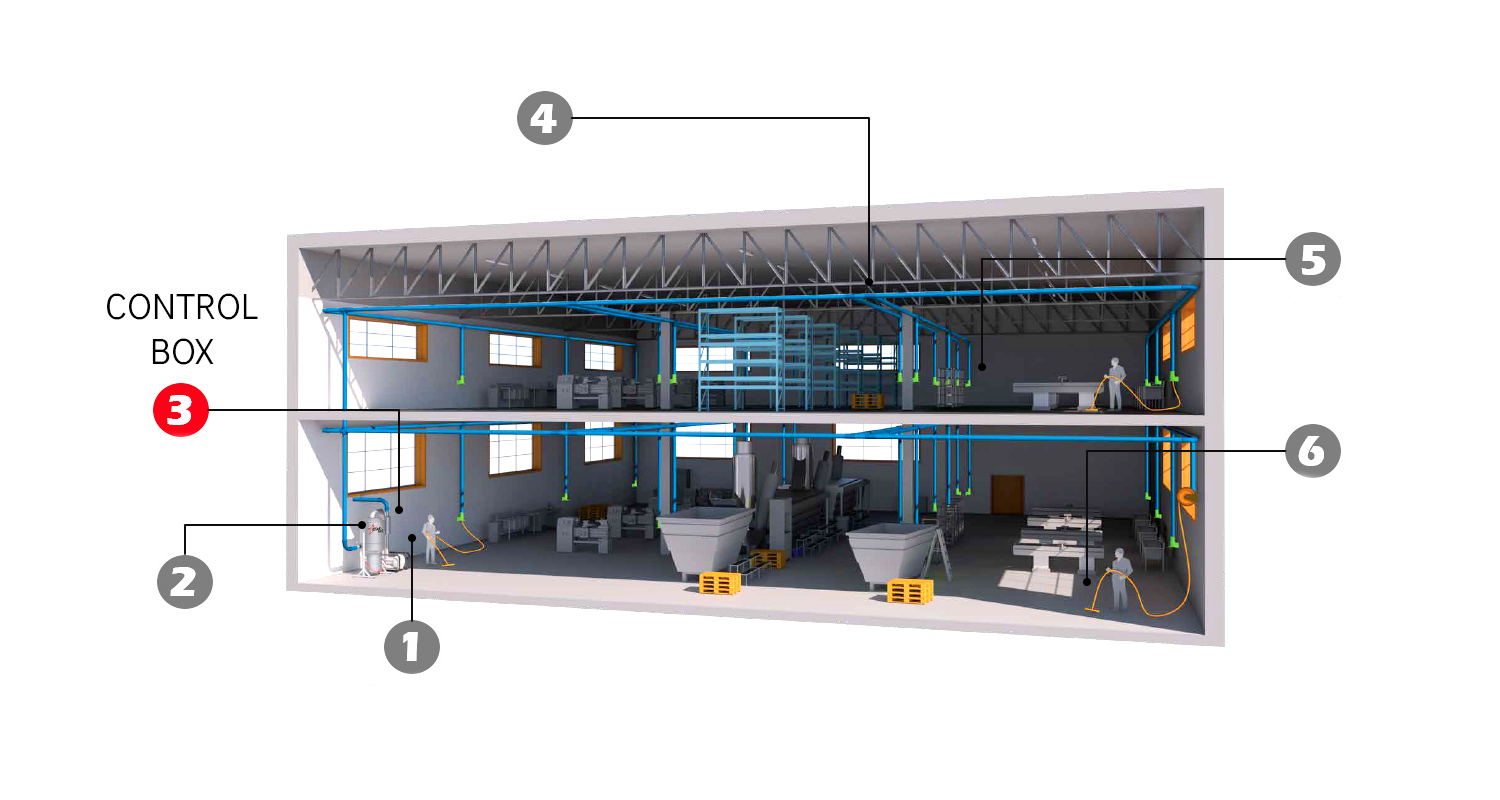

INDUSTRIAL CENTRAL VACUUM

An industrial central vacuum system can be listed in 6 main parts

BLOWERS | SEPARATORS | CONTROL BOX | TUBING SYSTEM | INLET POINTS | CLEANING TOOLS

BLOWER

SEPARATOR

Mechanical or cyclonic

CONTROL BOX

Can be a simple electric control box or include other sensors.

TUBING SYSTEM

Generally in metal, but also available in PVC.

INLET POINTS

From classical inlet valves to hose reels or other orifices.

CLEANING TOOLS

The vacuum accessories, flexible hoses and brushes.

CONTROL

BOX

The basic control boxes are plug and play. They include all parts to start and stop the blower remotely by a external start signal.

Further to this, the Inverter control box includes a pressure sensor. The inverter than will modulate the motor and try to keep the pre-set vacuum.

MORE POWER

BETTER EFFICIENCY

ATEX AVAILABLE

With SOFT-START

This control box includes a soft – starter, which will guarantee a smooth engine start and stop. This enhances the lifetime of the blower and eliminates all current peaks.

Please keep in mind, that a Soft-Start control box is not capable to modulate the motor at all.

CAP055

SOFT-STARTER

OPTIONAL AVAILABLE Control automatic filter cleaning | JPC.0. Control for modular blower | CMP004 Control for rotary valve | ROT00. Capacitive sensor | CPS100 Gate Valve control | GVC0.. PLC optional - Industry 4.0 | PLC001

Connection Voltage: 380 V Rated Current: 16 A Power: 5.5 kW Connection Frequency: 50 Hz Dimensions: 20Lx30Wx40H Resistance class: IP55 Weight: 9 kg

CAP075

SOFT-STARTER

OPTIONAL AVAILABLE Control automatic filter cleaning | JPC.0. Control for modular blower | CMP004 Control for rotary valve | ROT00. Capacitive sensor | CPS100 Gate Valve control | GVC0.. PLC optional - Industry 4.0 | PLC001

Connection Voltage: 380 V Rated Current: 24 A Power: 7.5 kW Connection Frequency: 50 Hz Dimensions: 20Lx30Wx40H Resistance class: IP55 Weight: 10.5 kg

CAP120

SOFT-STARTER

OPTIONAL AVAILABLE Control automatic filter cleaning | JPC.0. Control for modular blower | CMP004 Control for rotary valve | ROT00. Capacitive sensor | CPS100 Gate Valve control | GVC0.. PLC optional - Industry 4.0 | PLC001

Connection Voltage: 380 V Rated Current: 32 A Power: 12.5 kW Connection Frequency: 50 Hz Dimensions: 20Lx30Wx40H Resistance class: IP55 Weight: 12 kg

With INVERTER

This control box includes a Inverter and a pressure sensor. A smooth start/stop of the engine is gua-ranteed and, in addition, it will give the blower the ability to modulate.

This enhances the blowers range and will slow him down when less suction is needed and speed him up when more vacuum is needed.

In contrast to the Soft-Start solution, this one will drain less power, since it constantly measures the need of vacuum and controls the blowers RPM in base of the received data from the pressure sensor. With this solution maximum efficiency and maximum power are assured.

CFS055

INVERTER

OPTIONAL AVAILABLE Control automatic filter cleaning | JPC.0. Control for modular blower | CMP004 Control for rotary valve | ROT00. Capacitive sensor | CPS100 Gate Valve control | GVC0.. PLC optional - Industry 4.0 | PLC001

Connection Voltage: 380 V Rated Current: 26 A Nominal Power: 5.5 kW Connection Frequency: 50 Hz Max. Output Current: 23 A Max. Output Power: 15 kW Dimensions: 30Lx50Wx60H Resistance class: IP55 Weight: 15 kg

CFS075

INVERTER

OPTIONAL AVAILABLE Control automatic filter cleaning | JPC.0. Control for modular blower | CMP004 Control for rotary valve | ROT00. Capacitive sensor | CPS100 Gate Valve control | GVC0.. PLC optional - Industry 4.0 | PLC001

Connection Voltage: 380 V Rated Current: 34 A Nominal Power: 7.5 kW Connection Frequency: 50 Hz Max. Output Current: 30 A Max. Output Power: 19 kW Dimensions: 30Lx50Wx60H Resistance class: IP55 Weight: 18 kg

CFS120

INVERTER

OPTIONAL AVAILABLE Control automatic filter cleaning | JPC.0. Control for modular blower | CMP004 Control for rotary valve | ROT00. Capacitive sensor | CPS100 Gate Valve control | GVC0.. PLC optional - Industry 4.0 | PLC001

Connection Voltage: 380 V Rated Current: 49 A Nominal Power: 12.5 kW Connection Frequency: 50 Hz Max. Output Current: 44 A Max. Output Power: 28 kW Dimensions: 30Lx50Wx60H Resistance class: IP55 Weight: 25 kg

With SIEMENS

This control box offers the same characteristics, which are offered by the CFS versions. In addition to that option is that for our Premium version we use the latest SIEMENS inverters, giving the maximum quality you can get on the market.

CFP055

POWERED BYSIEMENS

OPTIONAL AVAILABLE Control automatic filter cleaning | JPC.0. Control for modular blower | CMP004 Control for rotary valve | ROT00. Capacitive sensor | CPS100 Gate Valve control | GVC0.. PLC optional - Industry 4.0 | PLC001

Connection Voltage: 380 V Rated Current: 28 A Nominal Power: 5.5 kW Connection Frequency: 50 Hz Max. Output Current: 25 A Max. Output Power: 16 kW Dimensions: 30Lx50Wx60H Resistance class: IP55 Weight: 18 kg

CFP075

POWERED BYSIEMENS

OPTIONAL AVAILABLE Control automatic filter cleaning | JPC.0. Control for modular blower | CMP004 Control for rotary valve | ROT00. Capacitive sensor | CPS100 Gate Valve control | GVC0.. PLC optional - Industry 4.0 | PLC001

Connection Voltage: 380 V Rated Current: 36 A Nominal Power: 7.5 kW Connection Frequency: 50 Hz Max. Output Current: 32 A Max. Output Power: 20 kW Dimensions: 30Lx50Wx60H Resistance class: IP55 Weight: 21 kg

CFP120

POWERED BYSIEMENS

OPTIONAL AVAILABLE Control automatic filter cleaning | JPC.0. Control for modular blower | CMP004 Control for rotary valve | ROT00. Capacitive sensor | CPS100 Gate Valve control | GVC0.. PLC optional - Industry 4.0 | PLC001

Connection Voltage: 380 V Rated Current: 52 A Nominal Power: 12.5 kW Connection Frequency: 50 Hz Max. Output Current: 47 A Max. Output Power: 30 kW Dimensions: 30Lx50Wx60H Resistance class: IP55 Weight: 28 kg

ACCESSORIES control box

Standard control automatic filter cleaning

JPC101/JPC201/JPC301

Surcharge for standard control unit of the automated filter cleaning system.

This optional uses a simple programmable timer (JPC200+300 a sequence timer), which every pre-set time cleans the filter automatically.

The timer will be mounted inside the main control box.

Advanced control automatic filter cleaning

JPC102/JPC202/JPC302

Surcharge for advanced control unit of the automated filter cleaning system.

This optional uses a differential pressure gauge, which continuously measures the filter status. A PLC continuously the status of the filter and when it reaches a certain dirtiness, it automatically cleans the filter.

If the filter (usually after years of use) can not be cleaned anymore by the automated cleaning system, the PLC emits a alarm to change the filter completely.

This solution will keep the system always running smoothly and will consume less pressured air than the standard control unit.

Control for modular blower

CMP004

Surcharge for control unit for max 4 modular blowers.

This optional is required when more than one blower is used.

Through a PLC, which is connected to two pressure sensors, a complex algorithm will switch on or off selectively blowers, ensuring always a great suction power with maximum energy savings.

Standard control for rotary valve

ROT001

Surcharge for standard control unit for the rotary valve.

This optional uses a simple programmable timer, which every pre-set time starts and stops the rotary valve, which discharges the dust.

The timer will be mounted inside the main control box and is free programmable.

Advanced control for rotary valve

ROT002

Surcharge for advanced control unit for the rotary valve.

This optional uses a sensor, which is connected to a PLC. The PLC evaluates the signal from the sensor and, if the cone is full, starts the rotary valve for a pre-set

time.

If, for any reason, the cone is not emptied by the rotary valve in a certain time, the PLC will emit a error signal to the operator, which has to check If the valve is working properly.

Gate Valve control

GVC004/GVC008/GVC012

This optional is used when automated valves for fully automated cleaning of a machine is used. Solenoid valves will command the main valves and open / close them accordingly.

It can be opened through a timer or through a pushbutton.

GVC004 can control up to 4 solenoid valves

GVC008 can control up to 8 solenoid valves

GVC012 can control up to 12 solenoid valves

Industry 4.0

PLC100

Standard HMI optional.

Monitoring through a display the following parameters:

1) The actual suction power;

2) The working time of each blower;

3) Dustbin full cycles (if sensor present) through display; Including standard display and PLC.

CERTIFICATIONS

Starvac company is certificated ISO 9001 and can achieve on the whole central vacuum system an ATEX Z22 standard.

Certificate of Conformity n. Q-2898-20

to ISO 9001:2015 standard

ATEX version Z22

Risk-free in case of organic dust

SYSTEM QUOTATION

Guaranteed answer, within 24 working hours.

Phone: +40 790 510 816

E-mail: office@starvac.ro

HEADQUARTER

Starvac SCS

via Rio Vallarsa, 5

I-39055 Laives (BZ)

WAREHOUSE

Starvac SCS

via Rio Vallarsa, 5

I-39055 Laives (Bz)

REGISTERED OFFICE

Starvac SCS ONLUS

Via Werner Von Siemens, 23

I-39100 Bolzano

EORI IT02989080219

HEADQUARTER

Starvac SCS

via Rio Vallarsa, 5

I-39055 Laives (BZ)

WAREHOUSE

Starvac SCS

via Rio Vallarsa, 5

I-39055 Laives (Bz)

REGISTERED OFFICE

Starvac SCS ONLUS

Via Werner Von Siemens, 23

I-39100 Bolzano

EORI IT02989080219