REFERENCES

The central vacuum system it’s perfect for all environments where the use of portable vacuum cleaners is difficult, for restricted space and ergonomics of production, or when portable vacuum cleaners are not efficient because of the dangerous and aggressive dust.

BASF 3D Printing

Heidelberg Deutschland

After examination of several offers the company decided the best project it was the one of Starvac, because of the excellent data log system, quality of materials and flexibility of the system, that it was not only for the cleaning dangerous fine 3D printing dust, but also for the combination with areal dust thru vacuum arms.

SAP120 Premium IE3 blower 18,6 kW – Inverter driven

Dust separator

SEP200 with 3 special M class filters, 24 sqm surface – Automatic filter cleaning with reverse pulse jet

Finishing

ATEX Z22

Piping

zinc coated steel (40mt Ø50; 10mt Ø76; 60mt Ø102; 30mt Ø154)

Vacuum points

8 metal inlet valves and 7 manoeuvrable vacuum arms

Location

Heidelberg GERMANY

Solina Hitchin

This is one of the most sophisticated central vacuum system never built for production industries, regarding starting, filter cleaning and data logs.

The material to be vacuumed is flour, so a particular difficult for stickiness and granulometry. The vacuum can be activated by pushing a button close to inlet points, then stopping by pressing again same button or after 5 minutes time. The cleaning of the filter by pressure air is automatic after the differential pressure switch. The discharge of the flour is in a big bag situated in a lower lever thru a pneumatic gate valve.

In the first 6 months or real operation, the system worked continuously for 1.600 hours, cleaning the 3 filters 2.300 times and emptying automatically the dust container 400 times.

Vacuum producer

SAP075 Premium IE3 blower 14,9 kW – Inverter driven

Dust separator

SEP200 with 3 special M class filters, 24 sqm surface – Automatic filter cleaning with reverse pulse jet

Finishing

ATEX Z22

Piping

zinc coated steel

Vacuum points

10 hose reels and 4 standard metal inlet valve

Location

Hitchin by London Luton UK

Solina Wroclaw

After the excellent performance given by the previous system in UK, the same company gave us another larger central vacuum system to get rid of the spilled flour.

The system was also fully installed by Starvac team from Italy during the lock-down and production started in July 2020.

Vacuum producer

SAP075 Premium IE3 blower 14,9 kW – Inverter driven

Dust separator

SEP200 with 3 special M class filters, 24 sqm surface – Automatic filter cleaning with reverse pulse jet

Finishing

ATEX Z22

Piping

zinc coated steel (430mt Ø50; 180mt Ø76; 150mt Ø102)

Vacuum points

23 hose reels each with accessories wall panel

Location

Wroclaw POLAND

Makyol – HZI Istanbul

This is nowadays the larges incinerator’s Europe, burning 1 million tons of waste and giving 25% of energy to the city of Istanbul. To clean the residual dust and debris they decided to install a central vacuum and we were selected for giving and high professional project support and outstanding quality material, with for instance a special reinforced zinc covering on the metal parts.

SAP075 Premium IE3 blower 14,9 kW – Inverter driven

Dust separator

SEP200 with 3 special M class filters, 24 sqm surface – Automatic filter cleaning with reverse pulse jet

Finishing

ATEX Z22

Piping

40ų zinc coated steel (40mt Ø50; 20mt Ø76; 200mt Ø102; 230mt Ø127)

Vacuum points

18 metal inlet valve with wall accessory panel

Location

Istanbul TURKEY

Finstral Unterinn

This company is an international market leader for PVC windows, and it is located just close to our HQ in Bolzano.

The central vacuum system was completely rebuilt and extended, to vacuum cleaning all the surface of the production halls, which is extruding in a 24-hour shift PVC profiles with special coverings.

SAP075 Premium IE3 blower 14,9 kW – Inverter driven

Dust separator

SEP200 with 3 special M class filters, 24 sqm surface – Automatic filter cleaning with reverse pulse jet

Piping

zinc coated steel

Vacuum points

24 standard metal inlet valve

Location

Unterinn Südtirol ITALY

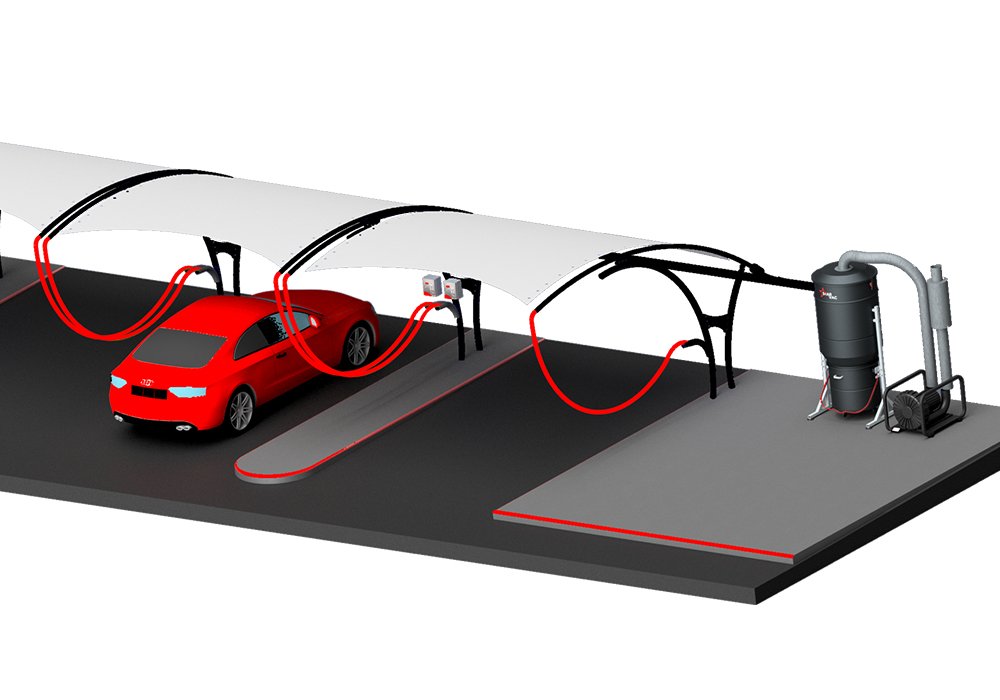

Volmer’s Car Wash – Sehnde

A brand-new carwash with a special vacuum section has been inaugurated in the nearing of Hannover. There are 6 stations, equipped with flexible hose coming from above and on both side, that permits a quick and convenient cleaning of car’s interiors. The cleaning area is covered, so the piping has been included in the structure.

Vacuum producer

SAP075 Premium IE3 blower 14,9 kW – Inverter driven

Dust separator

SEP100 with 3 special L class filters, 8 sqm surface

Piping

zinc coated steel

Vacuum points

12 metal inlet valve with flexible hose and a hard rubber crevice tools

Location

Sehnde GERMANIA

NOI Techpark

Makerspace

In the largest business incubator of Bolzano, all the start-ups and research company can use the Makerspace Labs. In 2018 Starvac installed a cleaning system with full metal pipe network, with standard inlet valves and some retractable hoses.

This central vacuum system covers 3 different main labs with a unit installed in the technical underground level: The first dedicated to wood working, the second to metal working and the third for 3D printing and general working.

Vacuum producer

SAS055 Standard blower 9,5kW – Inverter driven

Dust separator

SEP100 with standard L class filter, 8 sqm surface

Finishing

ATEX Z22

Piping

zinc coated steel

Vacuum points

8 with standard metal inlet valve + 2 upgrade with retractable hose

Location

Bolzano / Italy

PCB Drilling – Milano

This really special costumer from Milano, is one of the leading Italian PCB Printed circuit boards manufacturer in Italy.

He had the problem that the existing system was not powerful enough to properly vacuum all the fine dust forming when drilling the circuit boards. The dust was mainly spread all over the place, which lead in many subsequent problems.

After an on-site visit, the old central vacuum cleaner was exchanged and the tubing system was changed to provide proper suction power over all 10 automated PCB drilling machines.

Thanks to our upgrade, no more dust is spread into the air, and the output quality of the whole.

SAP120 Premium IE3 blower 18,6 kW – Inverter driven

Dust separator

SEP200 with 3 special M class filters, 24 sqm surface – Automatic filter cleaning with reverse pulse jet.

Additional Cyclonic separator made of hot dip galvanized steel with Big Bag.

Piping

zinc coated steel

Vacuum points

3 standard metal inlet valves

10 Direct connections to PCB drills

Location

Milano, ITALY

CERTIFICATIONS

Starvac company is certificated ISO 9001 and can achieve on the whole central vacuum system an ATEX Z22 standard.

Certificate of Conformity n. Q-2898-20

to ISO 9001:2015 standard

ATEX version Z22

Risk-free in case of organic dust

SYSTEM QUOTATION

Guaranteed answer, within 24 working hours.

Phone: +40 790 510 816

E-mail: office@starvac.ro

HEADQUARTER

Starvac SCS

via Rio Vallarsa, 5

I-39055 Laives (BZ)

WAREHOUSE

Starvac SCS

via Rio Vallarsa, 5

I-39055 Laives (Bz)

REGISTERED OFFICE

Starvac SCS ONLUS

Via Werner Von Siemens, 23

I-39100 Bolzano

EORI IT02989080219

HEADQUARTER

Starvac SCS

via Rio Vallarsa, 5

I-39055 Laives (BZ)

WAREHOUSE

Starvac SCS

via Rio Vallarsa, 5

I-39055 Laives (Bz)

REGISTERED OFFICE

Starvac SCS ONLUS

Via Werner Von Siemens, 23

I-39100 Bolzano

EORI IT02989080219